Copper Enameled Wire Magnet Wire Winding Wire

Product Paramenters

| Product Name | Copper enamelled wire |

| Origin | China |

| Province | Jiangsu |

| Brand | useful |

| Model | HBAIW 200 |

| Categories | Bare |

| Applications | Heating |

| Conductor material | Copper |

| Conductor type | Soild |

| Insulation material | HBAIW |

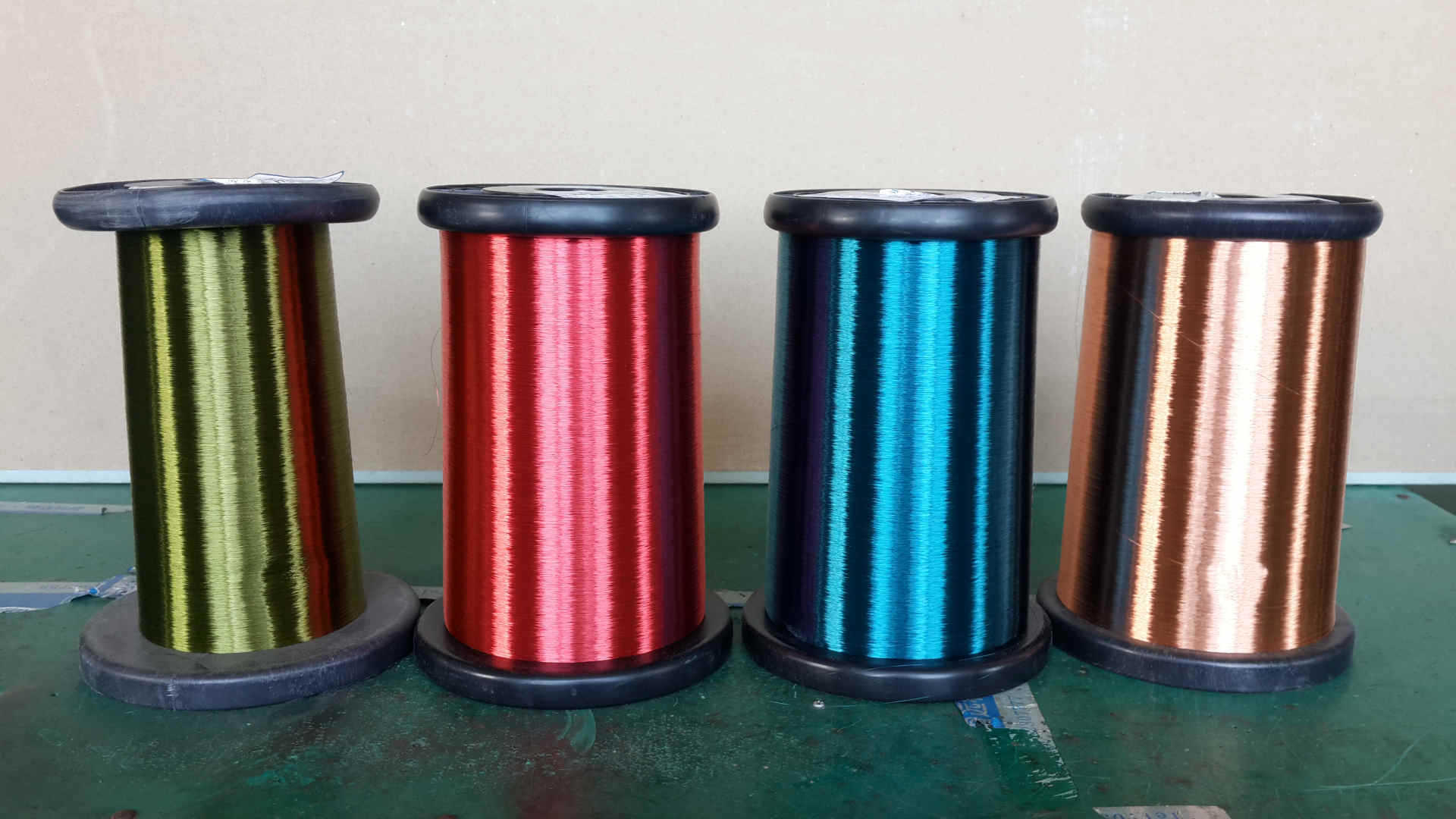

| Color | Yellow |

| Insulation | HBAIW 200 |

| Conductor | Single wire |

| Material | Single wire |

| Certification | UL/VDE |

| Rated Voltage | 220V |

| Standard | UL758 |

| Size | 0.8*3.8MM |

| Keyword | Copper Electrical Wire |

Enameled wire is a major type of winding wire, which is composed of conductor and insulating layer. After annealing and softening, the bare wire is painted and baked for many times. However, it is not easy to produce products that meet both standard requirements and customer requirements. It is affected by factors such as row material quality, process parameters, production equipment and environment. Therefore, the quality characteristics of various enameled wires are different, but they all have four properties: mechanical properties, chemical properties, electrical properties and thermal properties.

|

Product Name |

PEW |

PEWF |

EIW |

AIEIW |

PVF |

PIW |

|

Thermal Class |

130ºC |

155ºC |

180ºC |

200ºC |

120ºC |

240ºC |

|

Enamel Base Coat |

Polyester |

Modified Polyrster |

Polyester-Imide |

Polyester-Imide |

Polyvinyl formal |

Polyimide |

|

Cross Section Rnage |

0.1-6.5mm |

0.1-6.5mm |

0.1-6.5mm |

0.1-6.5mm |

0.1-6.5mm |

0.1-6.5mm |

|

Range of insulation thickness |

IEC 60317 |

IEC 60317 |

IEC 60317 |

IEC 60317 |

IEC 60317 |

IEC 60317 |

Acetal enameled wire,Polyester enameled wire,Polyurethane enameled wire,Modified polyester enameled wire

Polyester imine enameled wire,Polyesterimine/polyamidimide enameled wire,Polyimide enameled wire

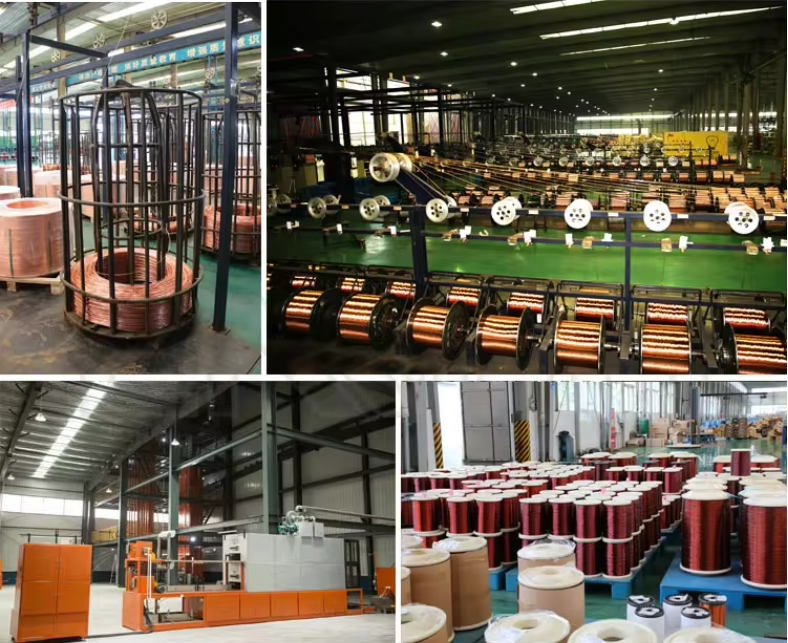

Our company mainly produces copper content 99.95% wire and cable with copper wire, large size aluminum rod, enameled aluminum wire, copper wire, copper clad aluminum wire. Our products are widely used in transformer, refrigerators, freezers, microwave ovens, air conditioners, fans, washing machines, compressor windings, vacuum cleaner windings and deflection coil of color televisions.

Features and Benefits

1) With good solderability, reduces coil production costs due to elimination of mechanical or chemical stripping.

2) Superior ''Q'' characteristic at high frequencies.

3) Excellent film adhension and flexibility.

4) Extremely resistant to a variety of solvents including most varnishes and hardener catalysts

Packing & Delivery