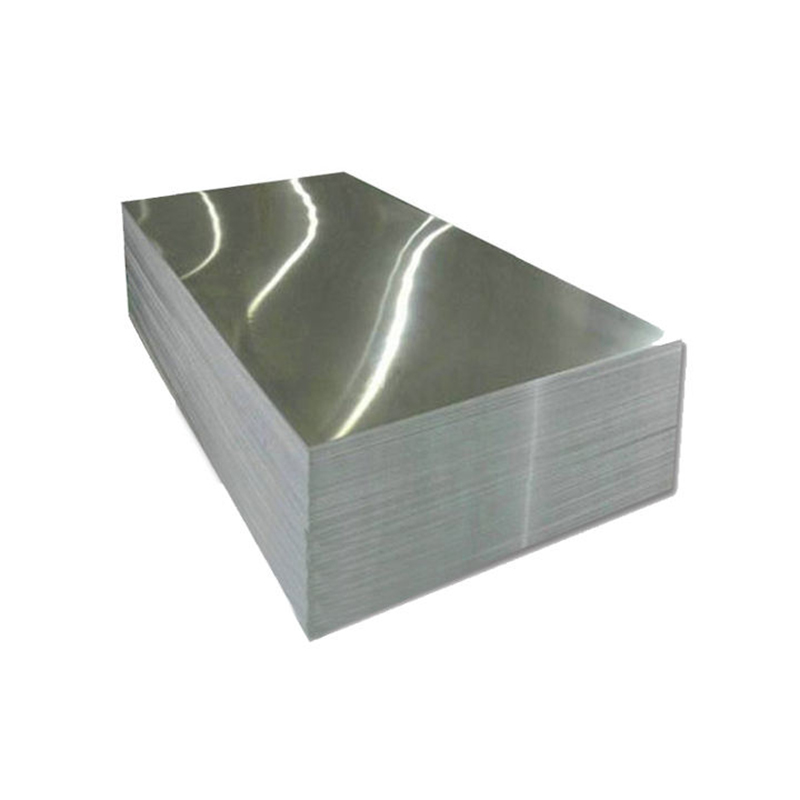

5mm 10mm thickness aluminium sheet 1050 1060 5754 3003 5005 5052 5083 6061 6063 7075 H26 T6 aluminum plate

Service

|

Mechanical Property |

||||||||

| ALUMINUM ALLOY | Grade | Normal Temper | Temper | Tensile Strength N/mm² | Yield Strength N/mm² | Elongation% | Brinell Hardness HB | |

| Plate | Bar | |||||||

| 1XXX | 1050 | O, H112, H | O | 78 | 34 | 40 | - | 20 |

| 1060 | O, H112, H | O | 70 | 30 | 43 | - | 19 | |

| Al-Cu (2XXX) | 2019 | O, T3, T4, T6, T8 | T851 | 450 | 350 | 10 | - | - |

| 2024 | O, T4 | T4 | 470 | 325 | 20 | 17 | 120 | |

| Al-Mn (3XXX) | 3003 | O | 110 | 40 | 30 | 37 | 28 | |

| 3004 | O, H112, H | O | 180 | 70 | 20 | 22 | 45 | |

| Al-Si (4XXX) | 4032 | O, T6, T62 | T6 | 380 | 315 | - | 9 | 120 |

| Al-Mg (5XXX) | 5052 | O, H112, H | H34 | 260 | 215 | 10 | 12 | 68 |

| 5083 | O, H112, H | O | 290 | 145 | - | 20 | - | |

| Al-Mg-Si (6XXX) | 6061 | O, T4, T6, T8 | T6 | 310 | 275 | 12 | 15 | 95 |

| 6063 | O, T1, T5, T6, T8 | T5 | 185 | 145 | 12 | - | 60 | |

| Al-Zn-Mg (7XXX) | 7003 | T5 | T5 | 315 | 255 | 15 | - | 85 |

| 7075 | O, T6 | T6 | 570 | 505 | 11 | 9 | 150 | |

Production Standard

As per international standard ASTM OR EN standard, all chemical composition, mechanical property, size tolerance, flat tolerance, etc strictly as per ASTM OR EN standard.

Features

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and EN

Specifications

Series:

1050, 1060, 1070, 1100, 1235

2A11, 2A12, LY12, 2024, 2014, 2017, 2219

3003, 3004, 3005, 3A21

5005, 5052, 5083, 5A02, 5754

6061, 6060, 6005, 6063, 6082, 6351, 6A02

7005, 7A04, 7A05,,7A09, 7050, 7075

8011

Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 5000mm ( Standard: 1000mm, 1219mm, 1250mm, 1500mm, 1540mm, 2000mm, 2100mm, 2200mm...2500mm) Length: Under 13000mm

Application

Aluminum material is light, strong, durable, and beautiful. It is widely used in various household appliances, electronic communications, medical, food packaging, printing, chemical, decoration ,aircraft fuel tanks.

Anodising is an electro-chemical process used to create a protective film of aluminium oxide on the surface of aluminium extrusion or sheet. As the aluminium oxide film is created from the aluminium itself, it is integral to the aluminium and cannot crack or peel. Anodising is translucent giving the aluminium a deep metallic luster and is extremely durable and continues to stand the test.

Using

Brand, display cabinets, indoor and outdoor building curtain wall decoration, elevator interior panels, ceiling integrated ceilings, kitchen appliance panels, household appliance panels, electronic product shells, automotive interior and exterior decoration, bags, jewelry boxes, handicrafts, lighting reflectors and lamp decoration, advertising word edges and hemming.

Advantage

1.Use coil anodizing Process is tightly controlled creating a uniform anodic layer resulting in a very consistent surface appearance and elegant colors, no visible iridescence.

2.Outstanding anti-fingerprint performance, scratch resistance

3.Eassy to cutting, bending,and embossing

4.It can be directly screen printed and etched, without pretreatment such as cleaning and degreasing and other pretreatment。

5.100% recyclable

Company Advantage

1.Factory price

2.20 years experience of aluminum business, are familiarity with oversea market.

3.Can do cutting, bending and embossing service

4.Free samples available for test